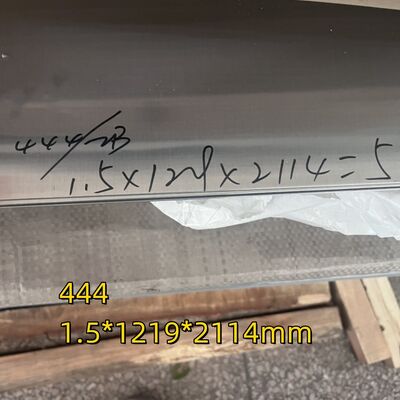

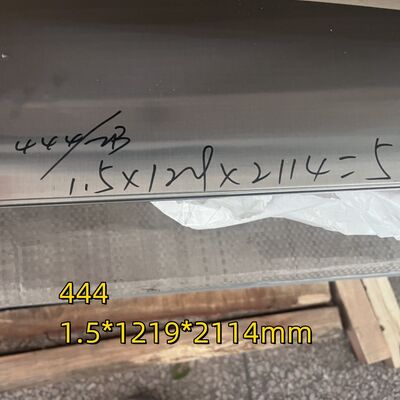

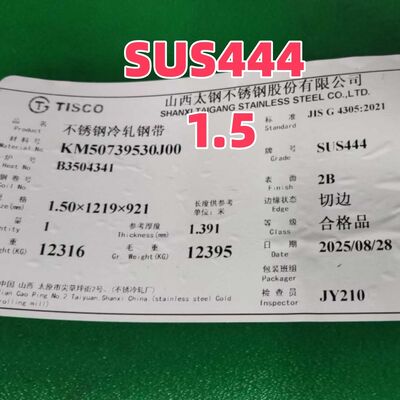

Material da chapa de aço inoxidável SUS444 THK 3MM, LENGHE 2440MM, WEDTH 1220M

| Nome do produto |

Chapa/folha de aço inoxidável |

| Commodity |

Austenítico, ferrítico, martensítico, duplex, laminado a frio, laminado a quente |

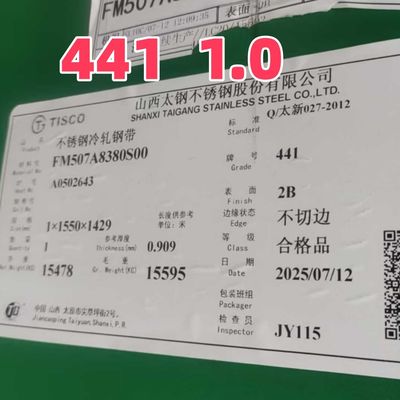

| Grau |

201, 202, 301, 304, 304j1, 304L, 321, 309s, 310s, 2205, 409L, 410, 410s, 420, 420j1, 420j2, 430, 439, ,430j1L,443, 444, etc. |

| Padrão |

ISO, JIS, ASTM, AS, EN, GB, DIN, JIS, etc. |

| superfície |

N0.1, N0.2, N0.3, N0.4, N0.5, N0.6, N0.7, N0.8, 2D, 2B, HL, BA, 6K, 8K, etc. |

| Duração |

1000 mm-11000 mm ou conforme exigência do cliente |

| Espessura |

0.3-100 mm |

| Largura |

600 mm, 1000 mm, 1219 mm, 1500 mm, 1800 mm, 2000 mm, 2500 mm, 3000 mm, 3500 mm ou conforme exigência do cliente |

| MOQ |

1 MT |

| Embalagem |

Padrão de exportação, navegável |

| Prazo de negociação |

FOB, CFR, CIF |

| Tipo de transporte |

Contêineres, granéis e comboios |

| Porto de carga |

Shanghai, Qingdao, Tianjin, etc. |

| Condições de pagamento |

T/T ou West Union |

| Prazo de entrega |

3 a 15 dias, dependendo das necessidades e quantidades dos clientes |

Cintas, bobinas, folhas, fios, ASTM A268, ASTM A240

Aplicações

Equipamentos de transformação de alimentos, de cervejaria e de vinificação, reservatórios de água quente, tubos de trocadores de calor e componentes para automóveis

Descrição

O tipo 444 é um aço inoxidável ferrítico com baixo teor de carbono, baixo teor de nitrogênio, que fornece resistência à corrosão de furos e fendas superior à maioria dos aços inoxidáveis ferríticos.Aplicações que exigem resistência à corrosão superior e resistência ao craqueamento por corrosão por estresse de cloreto são ideais para esta liga.

Química TÍPICA

Carbono: 0,025 máximo

Manganês: 1,00 máximo

Silício: 0.60

Cromo: 17,50-19.50

Níquel: no máximo 01.00

Molibdênio: 1.75-2.50

Titânio + Colúmbio: 0,20 + 4x (Carbono + Nitrogénio) min-0,80 max

Fósforo: 0,040 máximo

Enxofre: 0,030 max.

Ferro: Equilíbrio

Propriedades físicas

Densidade: 0,28 lbs/in3 7,75 g/cm3

Resistividade elétrica: microhm-in (microhm-cm):

68 ° F (20 ° C): 22,50 (57)

Calor específico: BTU/lbl° F (kJ/kg•K):

32 - 212 ° F (0 - 100 ° C): 0,102 (0,427)

Conductividade térmica: BTU/h/ft2/ft/° F (W/m•K)

A 212 °F (100 °C): 15,5 (26,8)

Coeficiente médio de expansão térmica: in/inl° F (μm/m•K):

32 - 212 ° F (0 - 100 ° C): 6,1 x 10 s (11,0)

Modulo de elasticidade: ksi (MPa)

29 x 103 (200 x 103) em tensão

Permeabilidade magnética: magnética

Intervalo de fusão: 2700 - 2790 °F (1482 - 1532 °C)

Formulários

Reboque - Faixa, Folha, Fios de fita - Perfil, redondo, plano, quadrado

Propriedades mecânicas à temperatura ambiente

PROPRIETADES: Anulado

Resistência à tração máxima: 60 KSI min (414 MPa min)

Resistência ao rendimento (0,2% de deslocamento): 40 KSI min (276 MPa min)

Prolongamento: 22% min.

Dureza: Rb 90 máximo

PROPRIETADES: Temperado

O tipo 444 pode ser laminado a várias temperaturas.

Propriedades adicionais

Resistência à corrosão

Para obter recomendações, consulte a NACE (Associação Nacional de Engenheiros de Corrosão).

Fim do processo

# 1 - laminado a quente, recozido e descascado.

# 2D - acabamento opaco produzido por laminação a frio, recozimento e descamação.# 2B - acabamento liso produzido por laminação a frioApós o recozimento com rolos polidos, é adicionado um passe de laminação a frio leve, dando-lhe um acabamento mais brilhante do que o 2D.

#BA- Brilhante, aquecido a frio, laminado a frio e aquecido a frio

#CBA- Curso brilhante anilhado acabamento fosco laminado e brilhante anil

#2 - laminados a frio

# 2BA - acabamento liso produzido por laminação a frio e recozimento brilhante.Um acabamento 2BA pode ser utilizado para aplicações de forma leve, quando se deseja um acabamento brilhante na parte formada. Polido - Vários acabamentos de grão para exigências específicas de acabamento polido.

* Nem todos os acabamentos estão disponíveis para todas as ligas - Contacte Ulbrich Sales para mais informações.

Fim de fio

XC - Extra limpo brilhante anelado ou brilhante anelado e laminado a frio Grease - Ultra-brilhante acabamento (para aplicações decorativas) Sabão - Sabão não é removido do fio temperado para agir como lubrificante.

* Contacte a Ulbrich Wire para acabamentos de fios personalizados.

Formação a frio

O tipo 444 oferece excelente formabilidade e pode ser facilmente puxado profundamente e girado.

Tratamento térmico

O tipo 444 não é tratável a calor.

Q1. Quais são os principais produtos da sua empresa?

A1: Os nossos principais produtos são chapa/folha de aço inoxidável, bobina, tubo redondo/quadrado, barra, canal, etc.

Q2. Onde está a sua fábrica?

A2: O centro de processamento da nossa empresa está localizado em Jiangsu, Wuxi, China.

Que está bem equipado com tipos de máquinas, tais como máquina de corte a laser, máquina de polir espelhos e assim por diante.

Podemos fornecer uma ampla gama de serviços personalizados de acordo com as necessidades dos clientes.

Q3:Como confirmar a Qualidade do Produto antes de fazer pedidos?

A3: Você pode obter amostras gratuitas para alguns produtos, você só precisa pagar o custo de envio ou organizar um correio para nós e tirar as amostras. O terceiro será aceito.

Q4. Quais são as vantagens da sua empresa?

A4: Temos muitos profissionais, pessoal técnico, preços mais competitivos e melhor serviço pós-venda do que outras empresas de aço inoxidável.

Q5. Quantos países já exportou?

A5: Exportados para mais de 50 países, principalmente da América, Rússia, Reino Unido, Kuwait, Egito, Turquia, Jordânia, Índia, etc.

Q6: Qual é o seu prazo de entrega?

A6: Para estoques, poderíamos transportar as mercadorias para o porto de carregamento dentro de 7 dias após recebermos o seu depósito

Para o período de produção, normalmente leva cerca de 15 dias a 30 dias após o recebimento do depósito.

P7: Pode fornecer uma amostra?

A7: Pequenas amostras em depósito e podem fornecer as amostras gratuitamente.

As amostras personalizadas levarão cerca de 5-7 dias.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!